Highest quality at any altitude

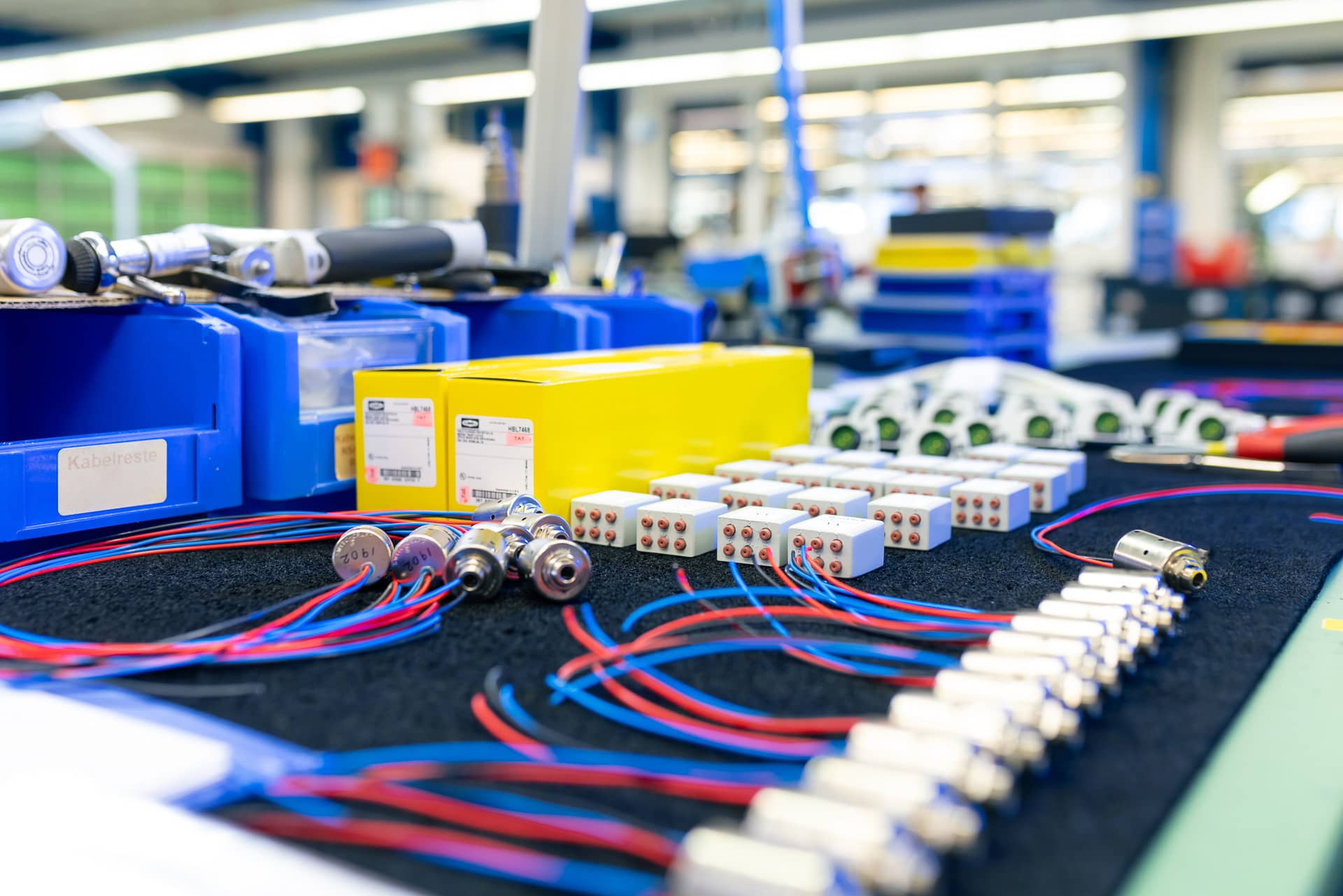

In Cockpit and on-board electronics, seats, cargo loading systems and test equipment, everywhere, aircraft manufacturers and their suppliers, airline operators and passengers rely on electromechanical and cable assemblies by rmw. In addition to quality and flexibility, rmw's long-standing business partners particularly appreciate the company's customer-specific production as well as its adherence to delivery dates.

Your advantages as a customer of rmw:

- Certification according to DIN EN 9100 (OASIS database)

- Use of AirSupply for customer orders

- Development and construction services

- High degree of mechanisation in production

- Cable processing and marking by laser

- 100% optical and electrical testing of all assemblies

- Inspection documents and required certificates (FAI according to EN 9102)

- Professional order processing, short response and delivery times

Portfolio: what rmw does for you

Complete systems

Circuit breaker panels, overhead panels for cockpits, electromechanical assemblies for cargo loading systems, cable assemblies for aircraft seats, pressure compensation systems and sensor cables for flight test systems – all this and more is manufactured by rmw according to your specifications.

Sub-assembly production

For its business partners, rmw helps to fulfil design-supporting services as well as the entire material purchasing. Moreover, rmw manufactures both customer and application-specific electromechanical sub-assemblies. These sub-assemblies are subjected to 100% electrical and optical testing before delivery.

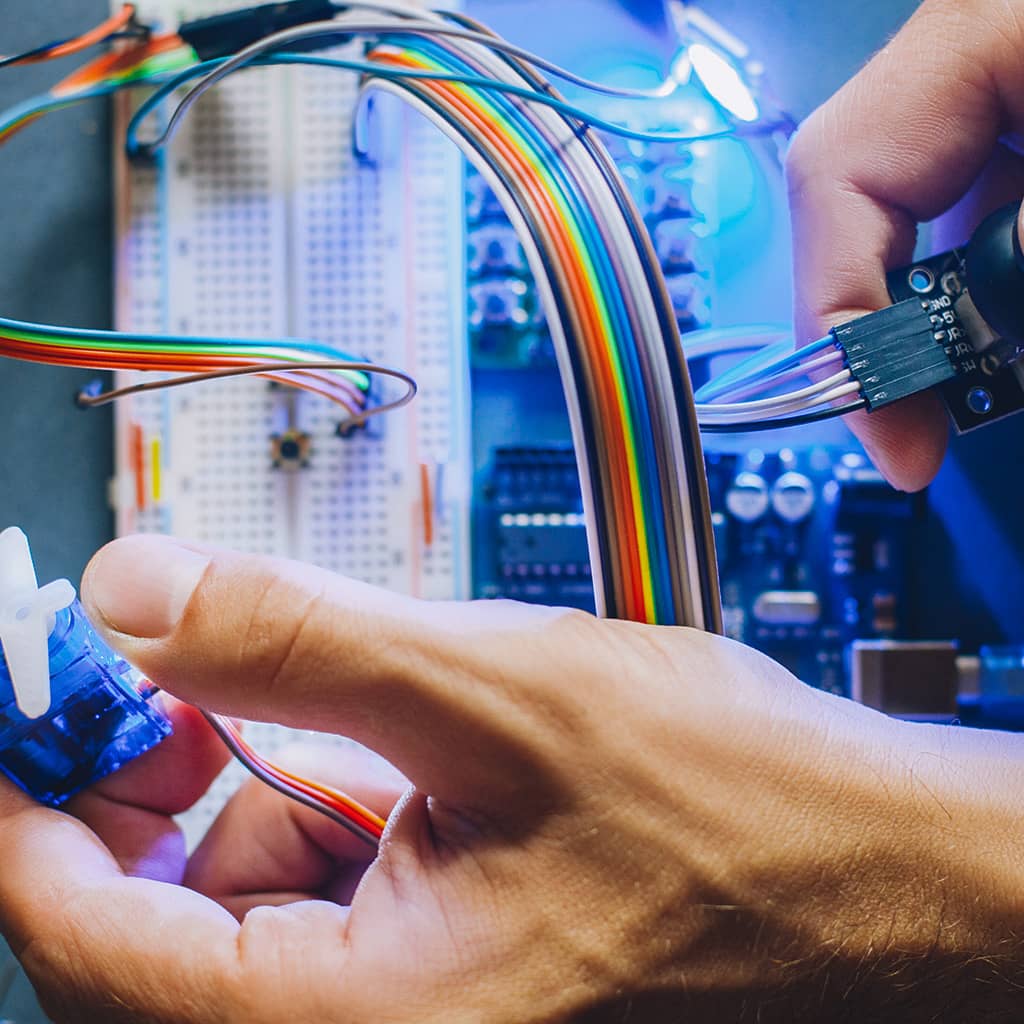

Assembly of components

As a reliable partner, rmw also carries out the mere assembly of components and the wiring of devices, promptly and flexibly. This is especially done when the customers are threatened with bottlenecks.

Laser cable marking

Approved for use in aviation: rmw marks raw cables according to your specifications, using modern, highly professional laser marking machines from Laselec.

Your connection to rmw

rmw specialists are looking forward to starting something new with you. For efficient consultation, please send us the key points and technical parameters of your project in advance.

Note: By sending us your enquiry, you agree to the processing of the data you have provided for the purpose of dealing with your enquiry. Find out more about data protection here.

* Mandatory

Your partner for development and construction

rmw specialists are happy to provide you with expert consultation and support in development and design.

rmw offers prototype production/sample construction, 0-series and transfer to series production. For many years, business partners have been taking advantage of the vast experience and expert knowledge of rmw in design support for the production of electromechanical sub-assemblies and cable systems.

In this case, your development department works closely with the rmw specialists.

They are capable of supporting you with the following:

- drawing production (using CAD software Solid Edge)

- creation of customer-specific production documents and documentation

- prototyping

- cost optimisation