The future at your fingertips instead of on the drawing board

3D printing opens up a wide range of possibilities for you to realise your ideas, develop new products or modify existing ones, time- and cost-efficiently. For example, if you need components for electromechanical assemblies or connectors that are not (yet) available the way you need them, rmw Kabelsysteme GmbH will develop them in cooperation with you.

Especially in the construction of samples and prototypes and in the construction of equipment, the 3D printers of rmw support you in testing the interaction of different components and configurations for their usability.

Your rmw services in 3D

- Support from prototype development to small series production

- Development and construction of components according to your requirement profile

- Checking your designs for feasibility

- Determination of weak points and potential for optimisation

- Printing and sampling of your components

- Optimisation about load capacity and surface quality

Available 3D printing materials

- Environmentally friendly PLA in various colours

- Durable nylon

- Flexible TPU

- Chemical resistant CPE

- Weather resistant ASA

- Water-soluble PVA support filament for printing complex geometries with strong overhangs

Your connection to rmw

rmw specialists are looking forward to starting something new with you. For efficient consultation, please send us the key points and technical parameters of your project in advance.

Note: By sending us your enquiry, you agree to the processing of the data you have provided for the purpose of dealing with your enquiry. Find out more about data protection here.

* Mandatory

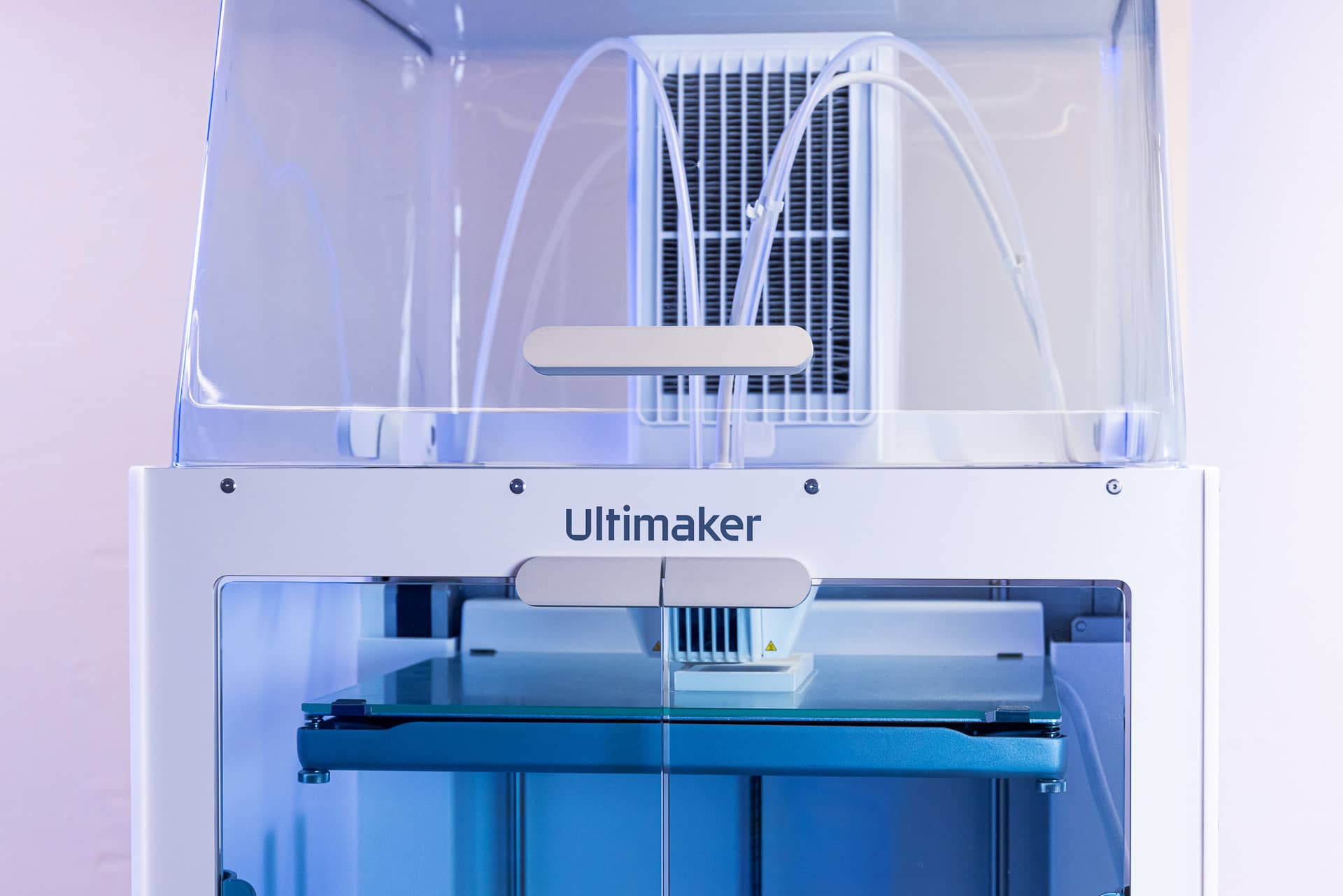

FDM 3D printing: Your project layer by layer

"Fused Deposition Modelling/FDM" is a modern 3D printing procedure in which a software divides a three-dimensional object into many layers and creates a contour to be printed for each layer. The printer then gradually applies this as molten plastic to a print bed. This is how your 3D object becomes real, layer by layer, at rmw Kabelsysteme GmbH.

Manufacturing portfolio

In the production of electromechanical sub-assemblies and cable assembly, rmw uses all established technologies.

HotMelt

Protect sensitive electrical components or realise unconventional connector shapes: With HotMelt, rmw offers you the solution.