Connections moving performance

You need a stranded wire or a 40-core cable for your project? rmw will take care of it with the same accurateness and reliability as with any other order.

Cable assembly according to individual specifications and requirements, the production of customised and high-performance connection solutions is in the DNA of rmw Kabelsysteme GmbH. First-class know-how, 30 years of experience, a comprehensive selection of materials and machinery for processing both standard and special cables provide the exact answer to every one of your cable challenges. With the desired secure connection from simple to complex, from cable lug to soldered connector, crimped or soldered by trained specialist personnel, rmw as your service provider manufactures and customises according to your customer specifications:

- Individual, flexible and able to respond quickly thanks to short distances within the company

- In the desired batch size; from prototype construction to small series production

- 100% visual and electrical inspection of every cable manufactured by rmw, according to test parameters specified by you

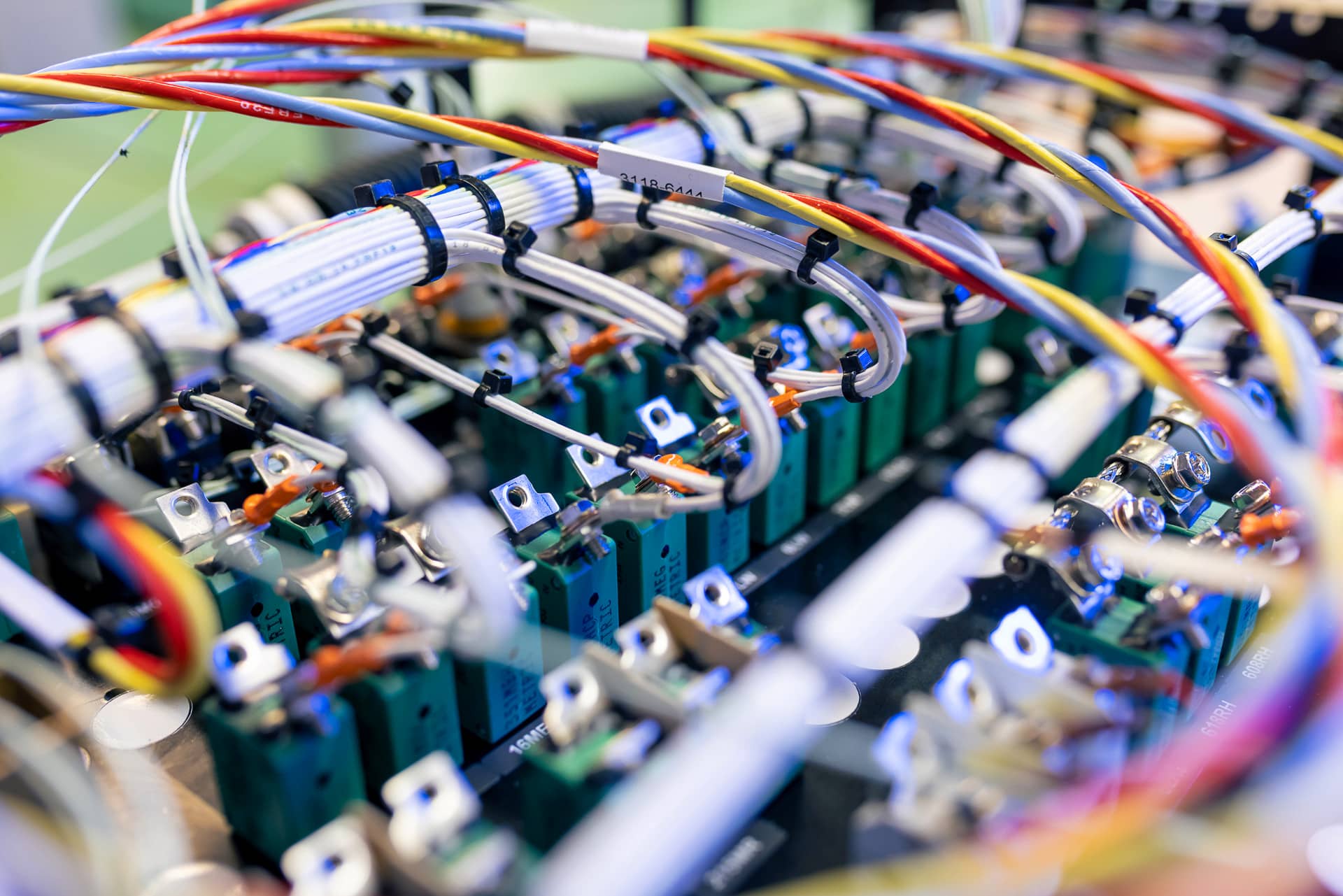

Customised cable assembly

rmw's customers manufacture highly specialised products; rmw follows this principle with customised individual cable assembly. From prototypes to small series, you as a customer of rmw will receive exactly the cable you require in exactly the batch size you need.

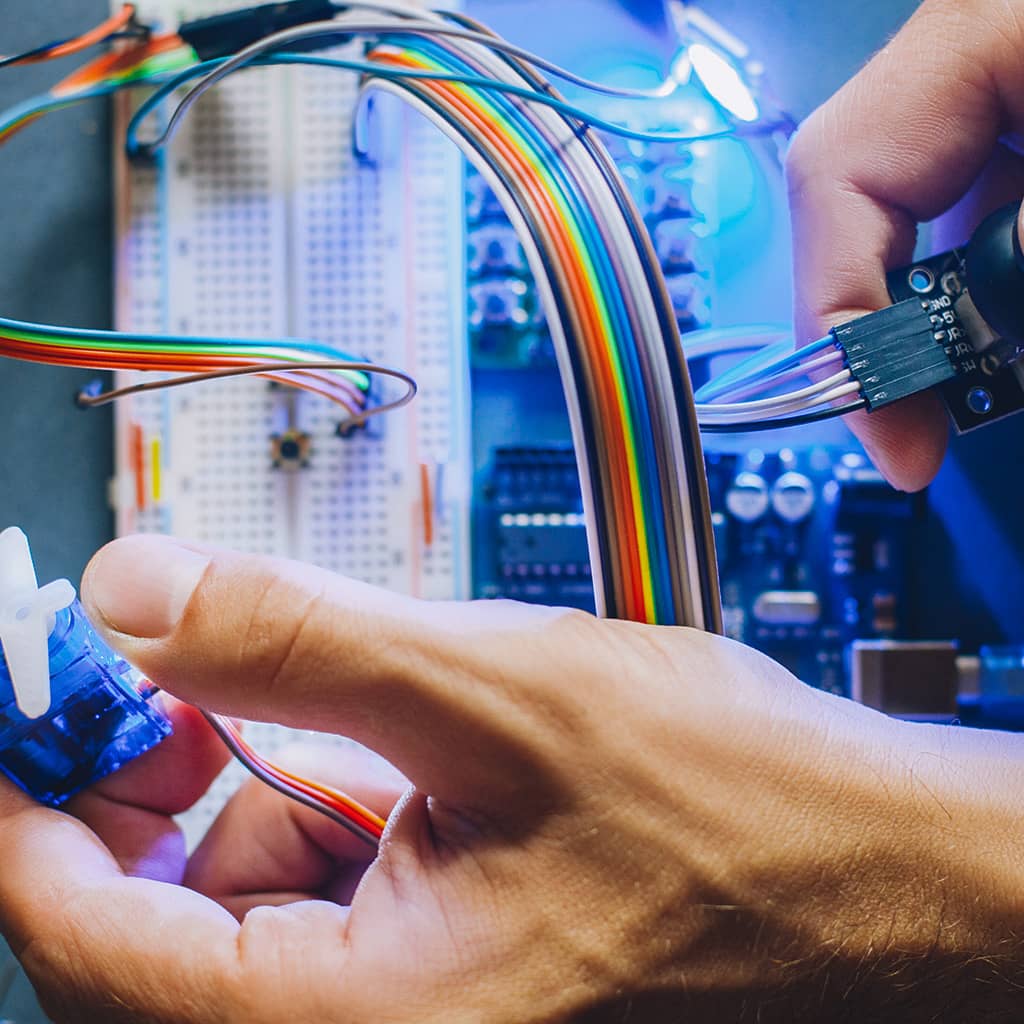

Cable processing

Stripping, crimping and soldering, laser-based stripping and marking: All this is part of the rmw cable processing portfolio. With its high-quality machine park, rmw always provides every service you require – in first-class quality.

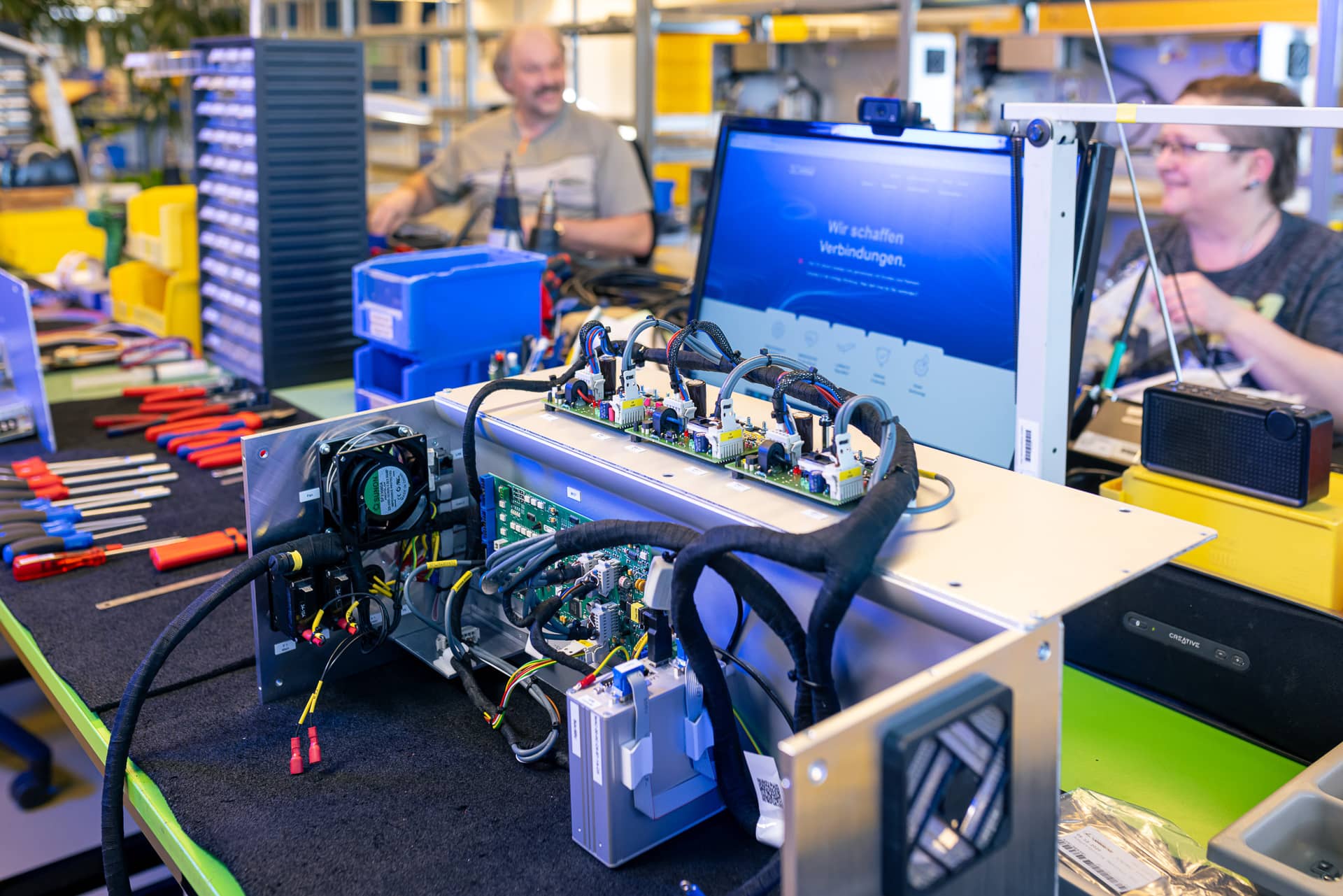

System wiring

Take advantage of rmw's extensive portfolio for planning, procurement and production of your systems. In addition to the production of customer-specific cable assembly, rmw views itself as your partner and service provider for system wiring. Cables, connectors, marking materials, moulding in the HotMelt procedure as well as electronic and mechanical parts will be assembled by rmw into complete systems according to your specifications.

EWIS

EWIS – electrical wiring interconnecting systems – (aerospace) refers to complete wiring systems in aircraft for power, data and signal transmission. As a successful Tier 1 supplier, rmw supplies its aerospace customers with individual, technically challenging electromechanical sub-assemblies, in accordance with the highest requirements, implemented in the company through certification in accordance with EN 9100.

Your connection to rmw

rmw specialists are looking forward to starting something new with you. For efficient consultation, please send us the key points and technical parameters of your project in advance.

Note: By sending us your enquiry, you agree to the processing of the data you have provided for the purpose of dealing with your enquiry. Find out more about data protection here.

* Mandatory

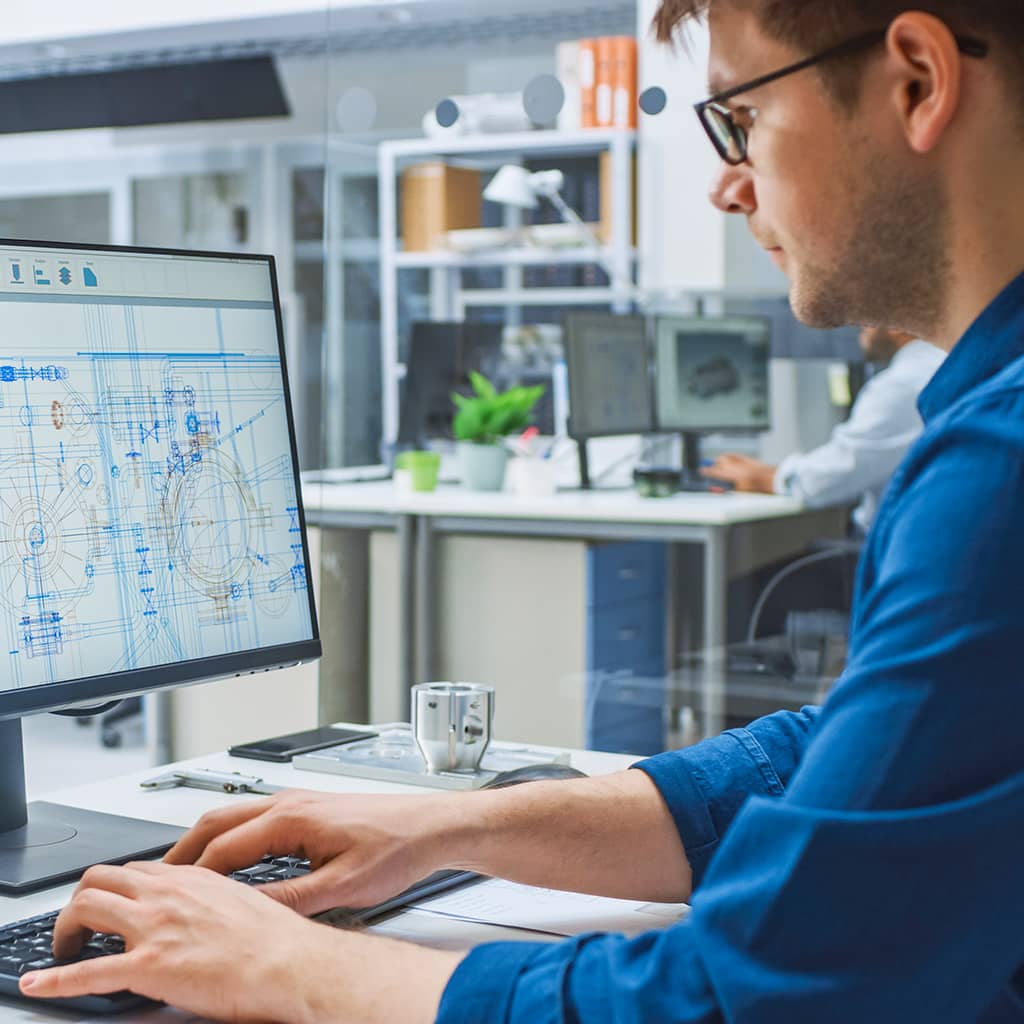

Your partner for development and construction

rmw specialists are happy to provide you with expert consultation and support in development and design.

rmw offers prototype production/sample construction, 0-series and transfer to series production. For many years, business partners have been taking advantage of the vast experience and expert knowledge of rmw in design support for the production of electromechanical sub-assemblies and cable systems.

In this case, your development department works closely with the rmw specialists.

They are capable of supporting you with the following:

- drawing production (using CAD software Solid Edge)

- creation of customer-specific production documents and documentation

- prototyping

- cost optimisation