Product safety – fits like a glove

Protect your important connections: With HotMelt, rmw Kabelsysteme GmbH offers you a high-quality low-pressure spraying process to reliably protect your components from external influences.

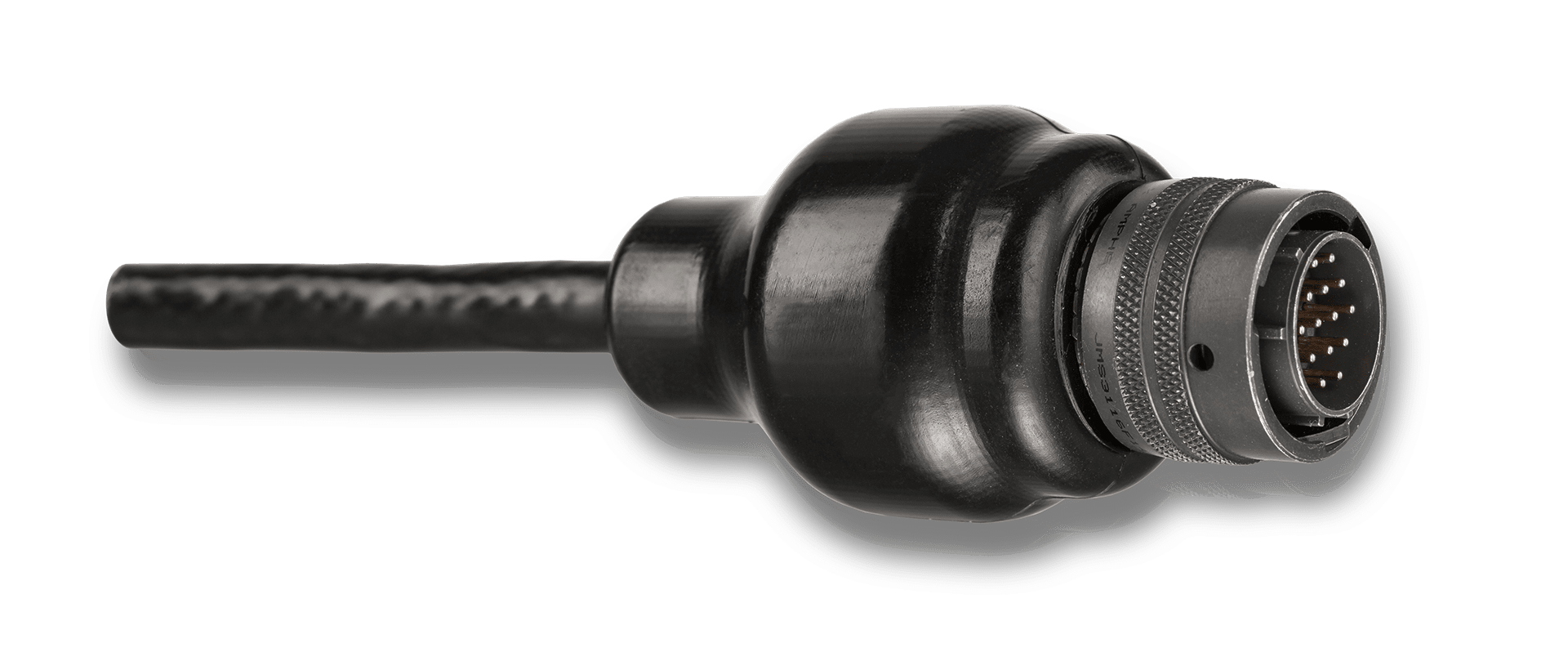

The socketing of a moulded connector not only serves as a housing, it also protects against unauthorised access and acts as an effective strain relief.

The compound used by rmw is compatible with electronic components and circuit boards of all kinds, without affecting any functionality. The required moulds are designed by rmw itself and manufactured using machining. Once again, rmw is your trusted provider, producing exclusively tailor-made service to meet your requirements.

How rmw HotMelt-protects your components

In the HotMelt process, thermoplastic high-performance polyamides are heated, melted and then injected under pressure into a mould. After a short cooling process, your finished component is removed.

HotMelt at rmw - your advantages:

- Homogeneous and bubble-free encapsulation of your protection-requiring components

- Wide thermal application range from -40 °C to 130 °C

- Reliable protection of moisture-sensitive components

- Good oil and UV resistance of your components

- Insulation effect and dielectric strength similar to ceramic materials

- Fire behaviour of the material classified according to UL94 standard with highest rating "V-0"

Your connection to rmw

rmw specialists are looking forward to starting something new with you. For efficient consultation, please send us the key points and technical parameters of your project in advance.

Note: By sending us your enquiry, you agree to the processing of the data you have provided for the purpose of dealing with your enquiry. Find out more about data protection here.

* Mandatory

Maximum fire safety: HotMelt at rmw

The classification according to UL94 ("Tests for Flammability of Plastic Materials for Parts in Devices and Appliances") is significant, especially for electronic components. The highest classification "V-0" of the HotMelt material used by rmw means, after a standardised test procedure, the generated flame extinguishes within a maximum of 10 seconds. Afterwards, the material must not glow for more than 30 seconds.

Manufacturing portfolio

In the production of electromechanical sub-assemblies and cable assembly, rmw uses all established technologies.

HotMelt

Protect sensitive electrical components or realise unconventional connector shapes: With HotMelt, rmw offers you the solution.